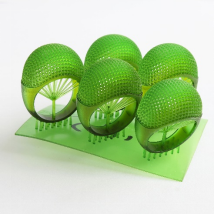

The 3D printing application is an additive manufacturing technology that uses bondable materials such as special waxes, powdered metals, or plastics to create three-dimensional objects based on digital model files.

Here's how it works:

? First, the software "slices" the 3D digital model into several planes and forms many sections.

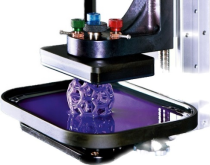

? A liftable platform is utilized with a liquid tank around this platform that is filled with a liquid that can be cured by UV irradiation.

? The UV laser starts from the bottom layer, cures the bottom layer, then moves down the platform, solidifies the next layer, and so on until it is finally formed.

At present, there are the following types of 3D printing technology:

1. SLS selective laser sintering

-The workbench is evenly spread with a very thin layer (sub-millimeter) of powder as raw material

- The computer controls the laser beam, which is scanned by a scanner

- The powder at the scanned position is sintered into solid sheets

- Repeat the above process until the model is printed;

- Excess powder is removed, the model is sanded and dried, and post-processing operations are carried out

- Applicable materials: powders of plastics, waxes, metals or their compounds

2. 3DP three-dimensional inkjet printing

- Spread the powder to the printing area;

- The printer nozzle is positioned in the cross-section of the model and sprays the binder;

- The powder feeding piston rises one layer and the solid model descends one layer to continue printing;

- Repeat the above process until the model is printed;

- Excess powder is removed, the model is cured, and post-processing operations are carried out

- Applicable material: high-performance composite materials (high-strength printing powder)

3. FDM fused deposition manufacturing

- Applicable materials: plastic, wax, resin, nylon

4. SLA light curing molding

-Based on the polymerization reaction of photosensitive resins

- Computer-controlled ultraviolet laser to scan the liquid resin point by point

– The thin layer of resin being scanned produces a polymerization reaction that forms lines from dots and finally a cured cross-section

– When one layer has cured, move one layer up and down to cover the new liquid resin

- And so on until the entire part prototype is made.

- Applicable material: photosensitive resin

5. DLP light curing molding

- High-resolution digital light processor (DLP) projectors are used to cure liquid photopolymers

- Computer-controlled projector for surface scanning of liquid resin

- Layer by layer flake curing

- And so on until the entire part prototype is made.

- Applicable material: photosensitive resin

6. Bio-3D printing

- The 3D bioprinter has two print heads, which place the human cells and the bio-paper

- A 3D model of an organ or artery is first "printed", and then one layer of cells is placed on top of another.

- After printing a circle of "bioink" cells, print a "biopaper" gel.

- Keep repeating this process until the new organ is printed.

- Naturally occurring cells begin to reorganize, fuse, and form new blood vessels. It takes about an hour for each blood vessel to form, while it takes several days for them to fuse together.

- Applicable material: Bioink containing living cells