3D SPI (Solder Paste Inspection) refers to the three-dimensional solder paste inspection system, the main function is to inspect the quality of solder paste printing, including volume, area, height, XY offset, shape, bridging, etc. How to quickly and accurately detect very small solder paste, generally using PMP (phase modulation profile measurement technology) and Laser (Chinese translated as laser triangulation technology) detection principle.

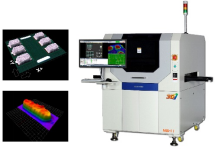

3D AOI (Automated Optical Inspection), the full name in Chinese is three-dimensional automatic optical inspection instrument, which is based on optical principles to optical inspection equipment for common defects encountered in welding production.

Due to the lack of 3D information, traditional 2D AOI has a bottleneck in many quality inspections. Compared with 2D image information, 3D AOI can provide depth information, which can be better applied to defect detection.

At present, the mainstream 3D measurement technology includes binocular stereo vision, TOF (time flight method), speckle measurement, and structured light methods, among which, the 3D sensing technology based on surface structured light projection is more suitable for 3D SPI/3D AOI in terms of price, point cloud accuracy, point cloud resolution and 3D measurement speed, so this technology is widely used in 3D automatic optical inspection technology.

Features of 3D SPI/AOI based on surface structured light:

(1) Different from the traditional surface structured light projection technology, 3D SPI/3D AOI In order to cater to the 2D automatic optical detection technology, the lens equipped with the camera is usually a telecentric lens, which has the advantage of small distortion and small depth of field;

(2) In order to better reconstruct the missing three-dimensional information of the viewing angle, 1-2 DLP projectors are generally used in 3D SPI, and 4 DLP projectors are used in 3D AOI;

(3) Due to the small measurement field of view (20mm-50mm), the traditional DLP projector offset placement will have part of the picture out of focus resulting in a decrease in accuracy, in order to cooperate with 3D AOI detection, our company has specially developed a DLP tilt-shift projector, so that when the projector is offset and placed, the public field of view of the camera is fully focused, which is conducive to maximizing the measurement depth of field.